Flexographic Plates for Alignment Film Printing

—Corner and Edge

Improvement Technologies

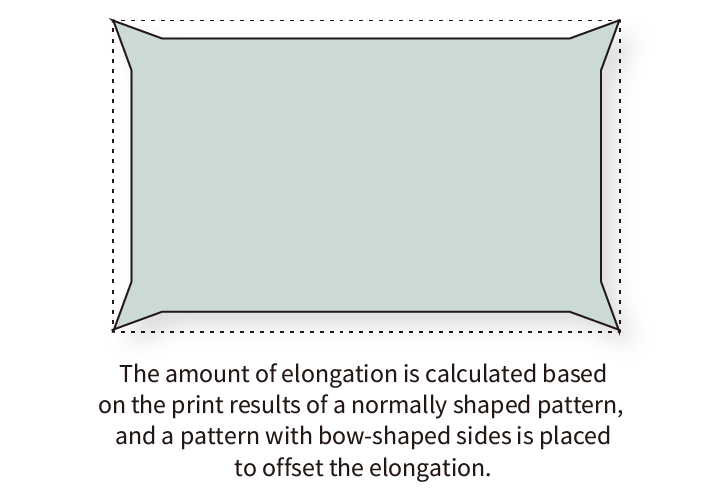

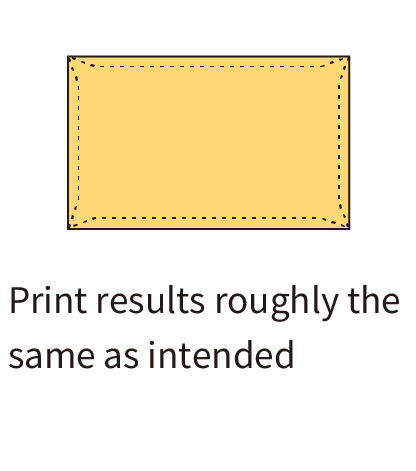

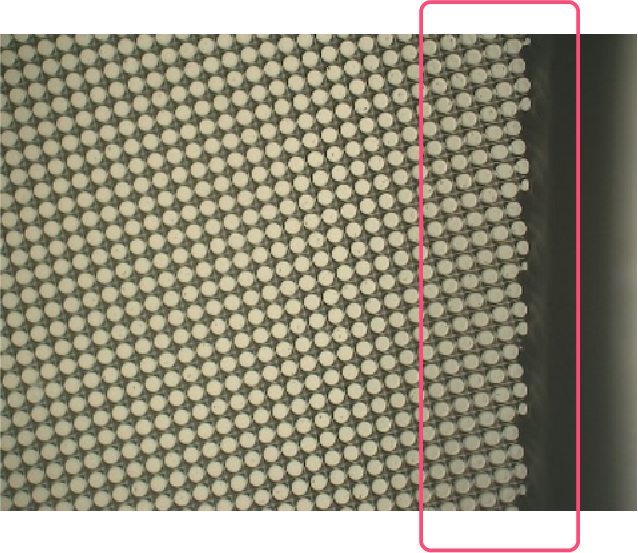

Technology to improve printing quality on corners

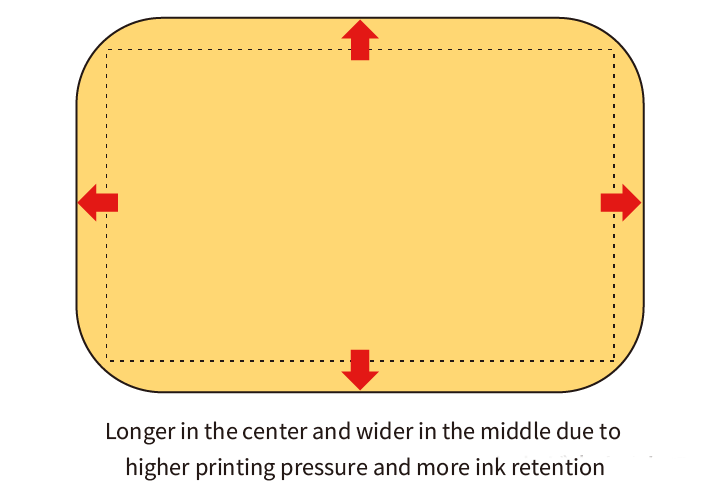

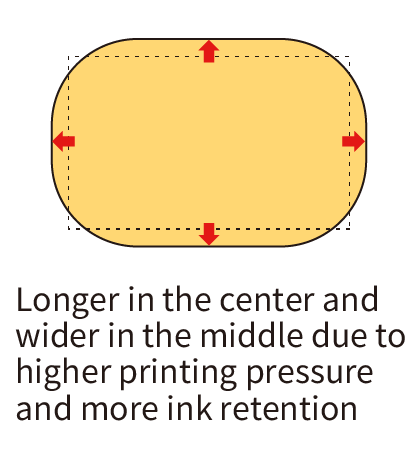

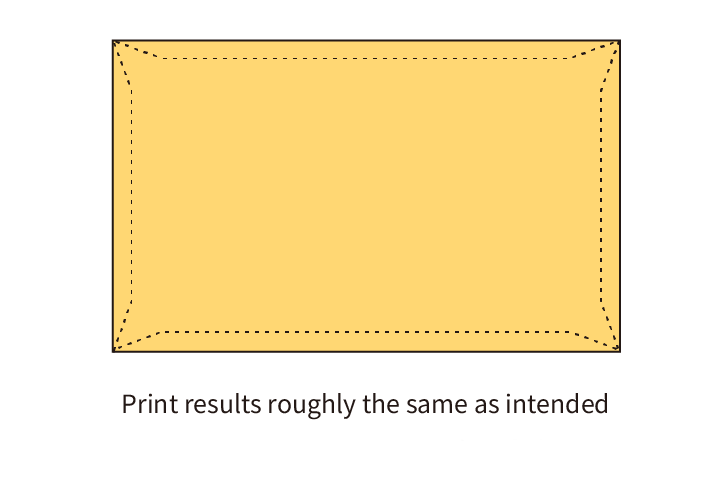

When printing, the ink spreads differently at the corners and around the center of the pattern.

In general, ink does not spread well in the corners, and it is likely that ink will not be applied to the entire area that needs to be inked.

We at Komura-Tech design patterns whose corners are specifically shaped to ensure high printing quality on corners.The shape can be adjusted according to your request.

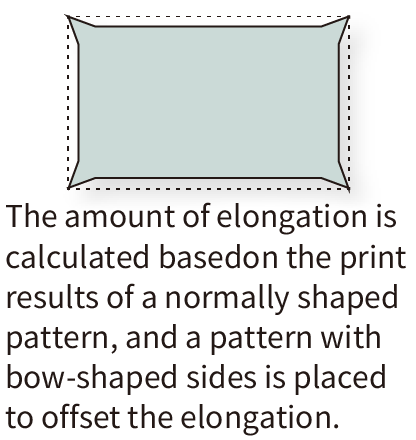

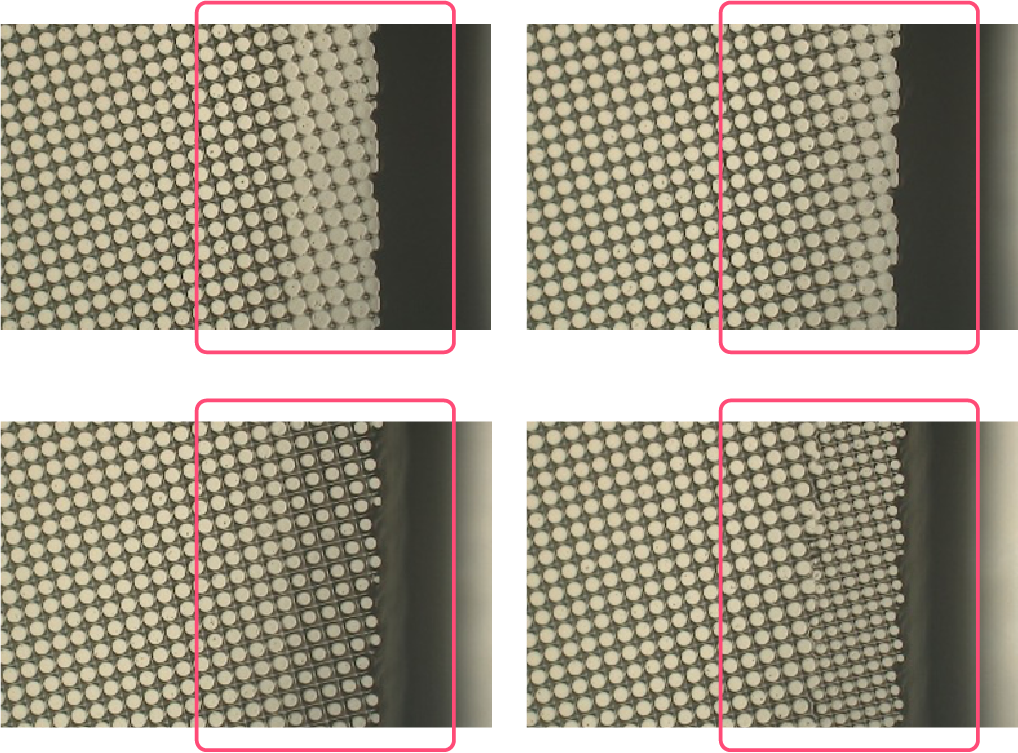

| Normally shaped | Bow-shaped sides (with corners) | |

|---|---|---|

| Pattern shape |

|

|

|

|

|

| Print result |   |

|

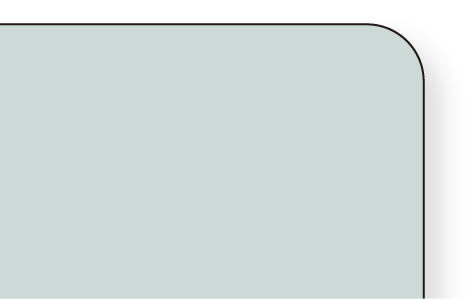

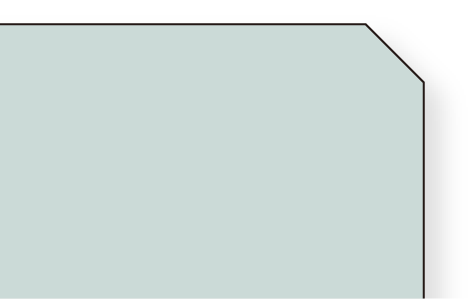

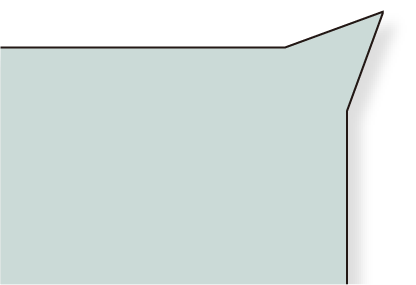

Examples of special corner shapes

You can select the optimal corner shape based on the characteristics of the ink and plate you use.

- Round

- Truncated corners

- Bow-shaped sides with corners

- Special bow-shaped sides

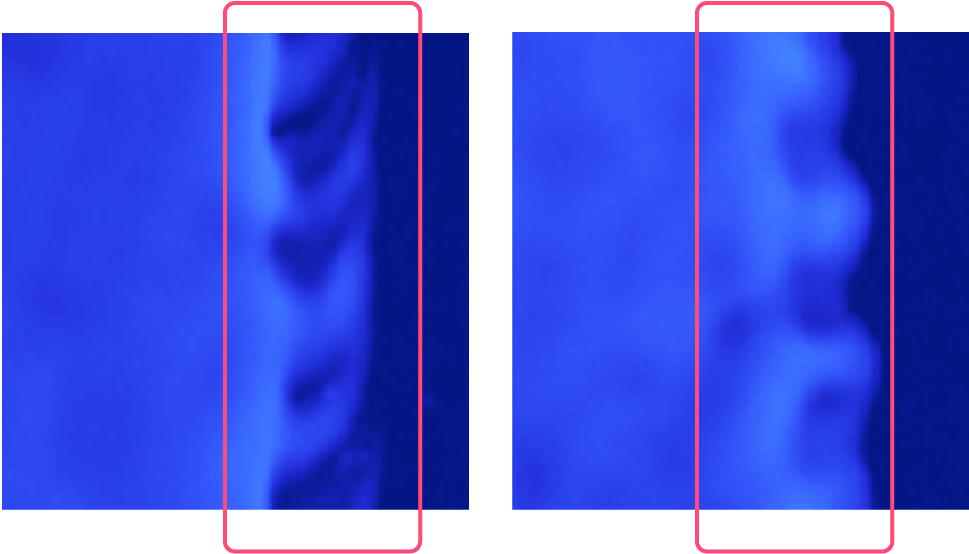

Edge improvement technology (for alignment film printing)

Marginal zone (MZ) processing technology

Edges are prone to under-application or buildup of ink, which makes it difficult to control film thickness and linearity.

In particular, liquid crystal panels in recent years have become increasingly high-definition and narrow-framed, requiring high precision even at the edges.

We at Komura-Tech perform special (marginal zone, or MZ) processing on the end faces of patterns to control printing quality at the edges.

Based on our internal evaluation results and the technologies you have adopted, we propose MZ processing tailored to your purposes.

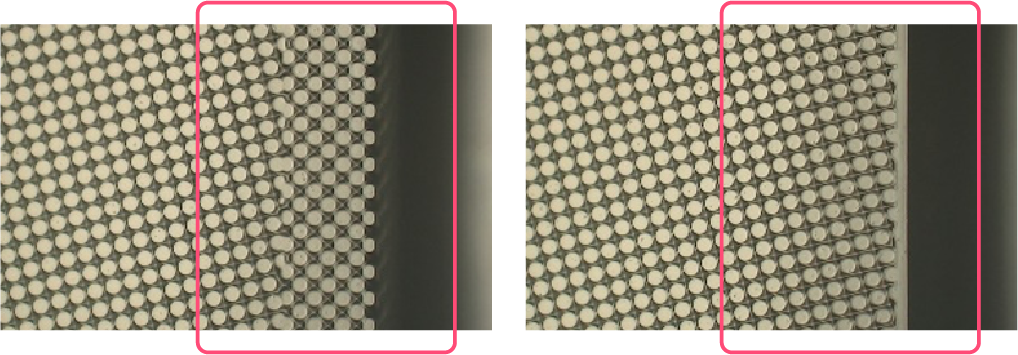

Without edge processing

- Print results (edges)

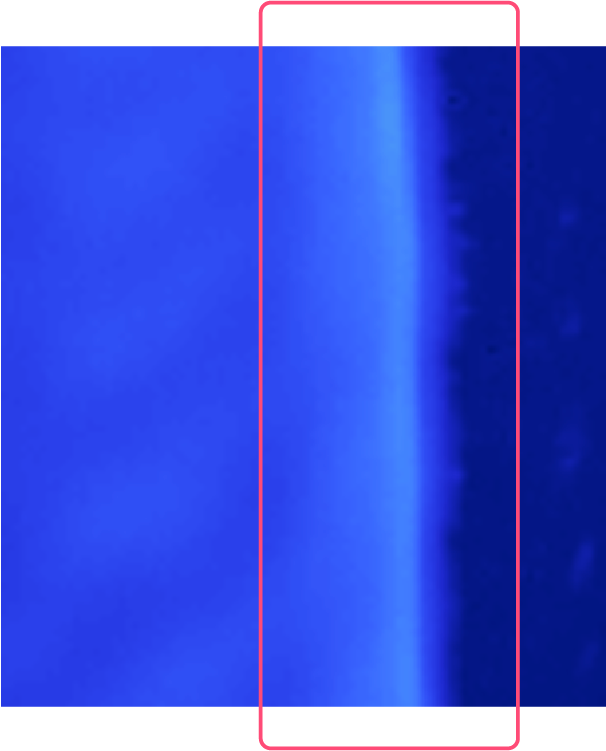

With MZ processing, which is effective for controlling film thickness at the edges

- Print results (edges)

By changing the size and pitch (number of lines) of the halftone dots, you can adjust the amount of ink retained on the end faces of the pattern and thus control the film thickness.

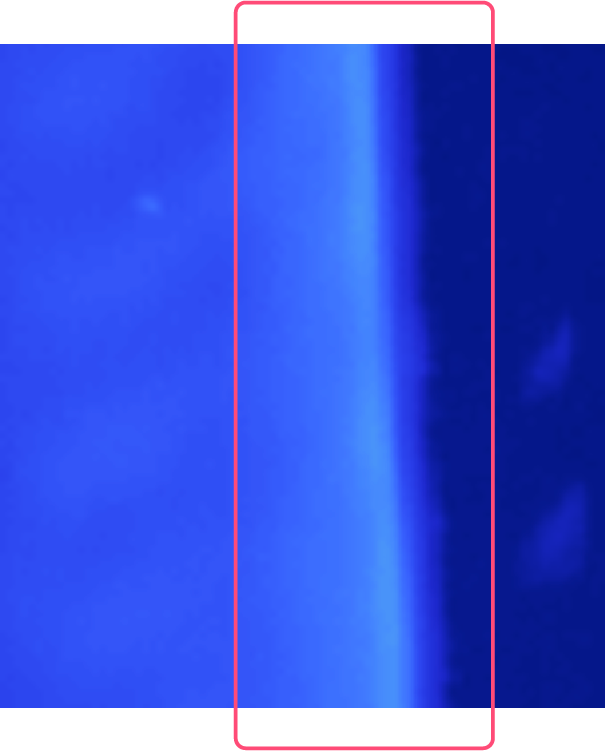

With MZ processing, which is effective for controlling linearity at the edges

- Print results (edges)

By changing halftone dot angles or adding borders (solid, or without halftone dots), you can change the flow of ink and improve linearity.