Flexographic Plates for Alignment Film Printing

—Major Features

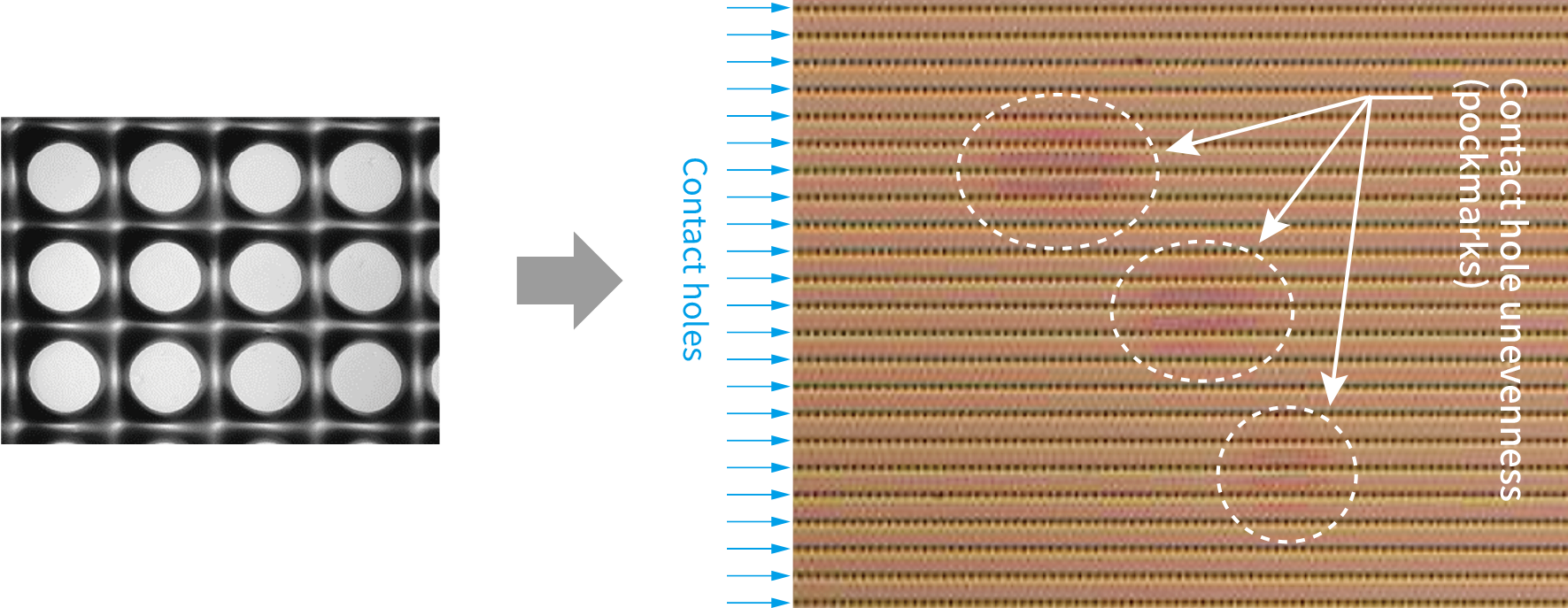

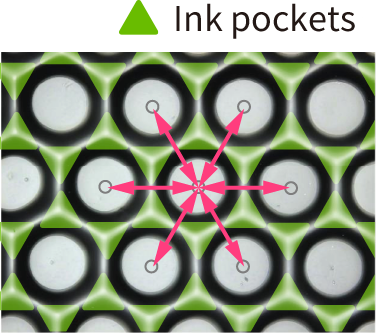

Problem with conventional halftone dots: Contact hole unevenness

We took a fresh approach to preventing contact hole unevenness (pockmarks) on the array side.

Halftone dots in the conventional

orthogonal patterning

Proposal of two new types of halftone dot patterning

Our flexographic printing plates are aimed at the printing of smooth film on liquid crystal glass substrates.

In addition to conventional orthogonal patterning, we propose two new halftone dot designs.

| Comparison with conventional halftone dot patterning | |||

|---|---|---|---|

| Patterning | New halftone dot patterning 1 Honeycomb patterning |

Conventional halftone dot patterning Orthogonal patterning |

New halftone dot patterning 2 Isotropic patterning |

|

|

|

|

| Major Features | Specifically designed for uniform ink application For high-definition panels |

Basic patterning Used for various products |

Specifically designed to eliminate unevenness specific to regular patterning Highly versatile and not limited to certain models |

Approach to preventing alignment film contact hole unevenness by using new halftone dot patterning

For high-definition panels

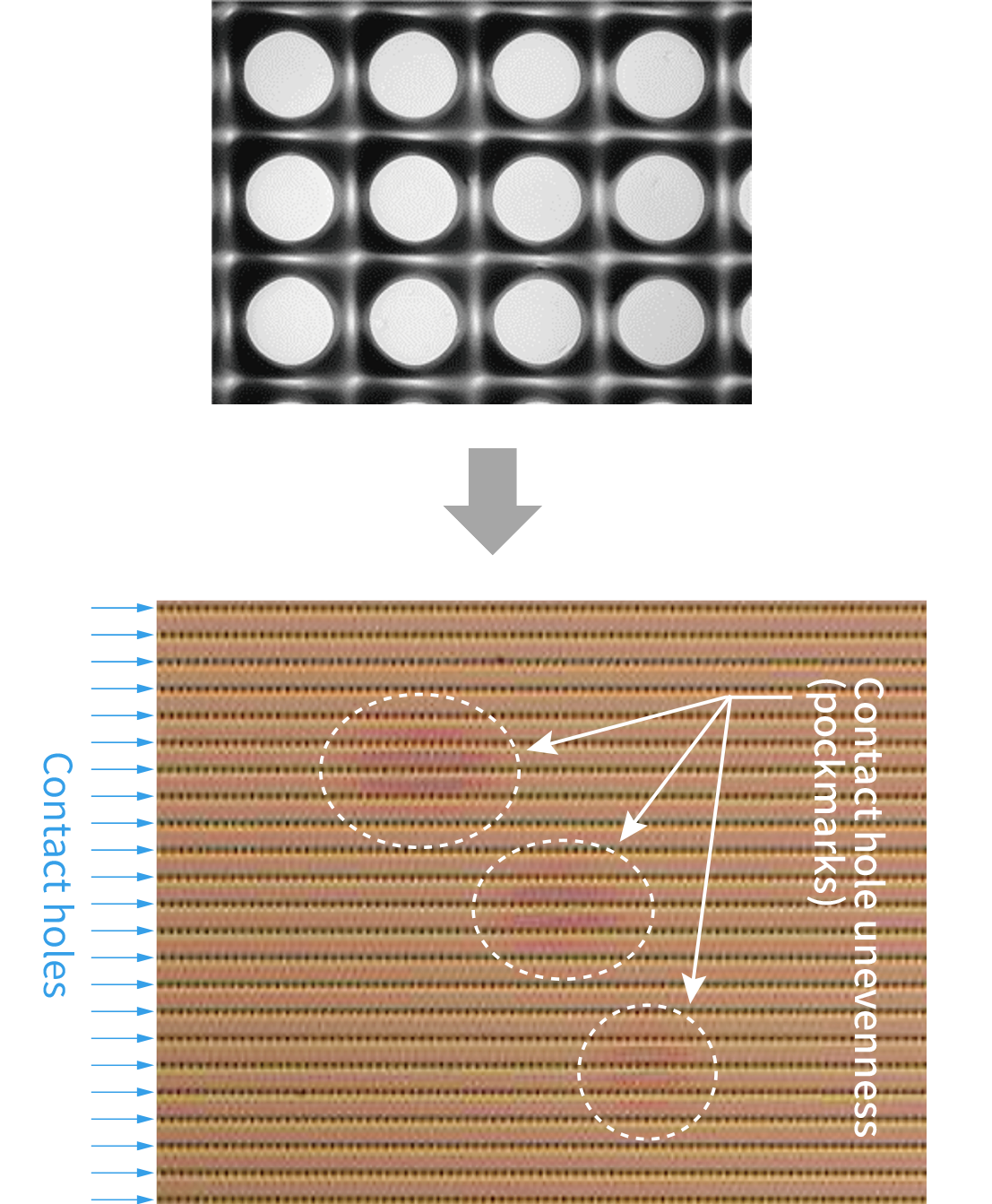

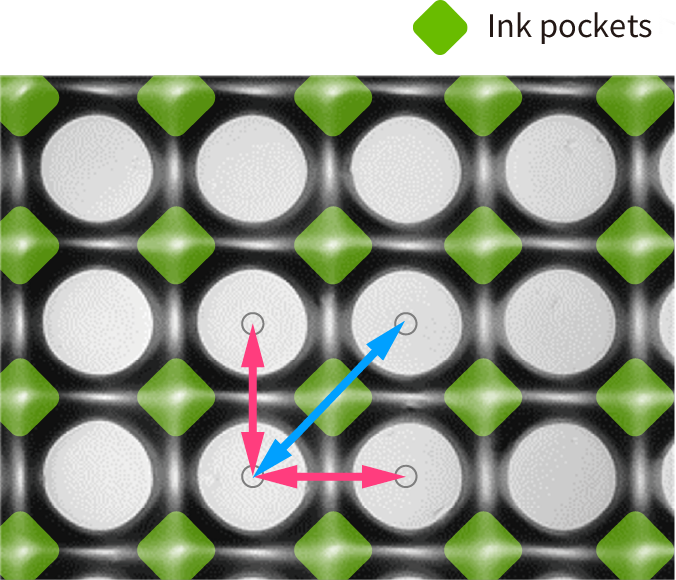

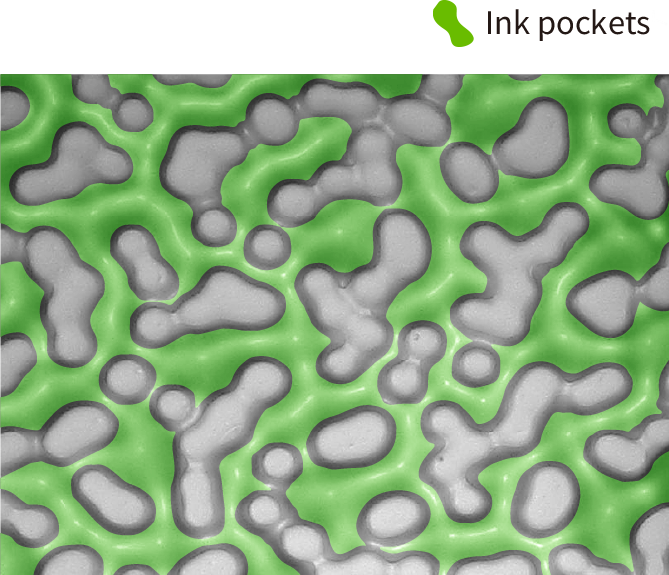

Honeycomb patterning

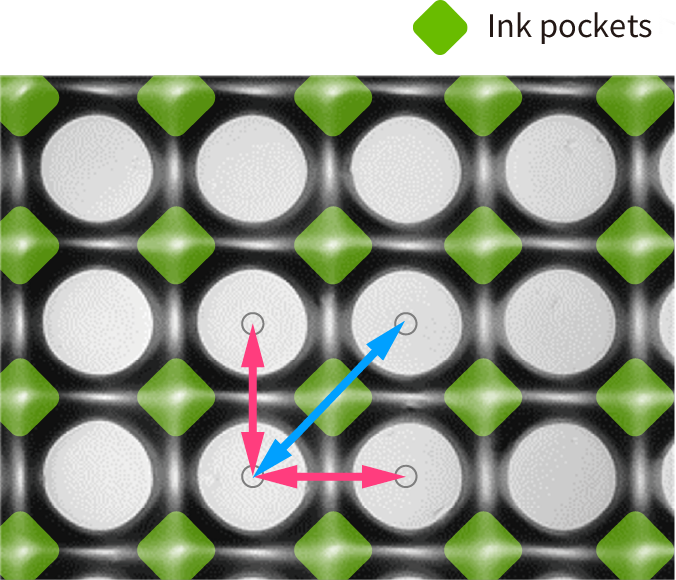

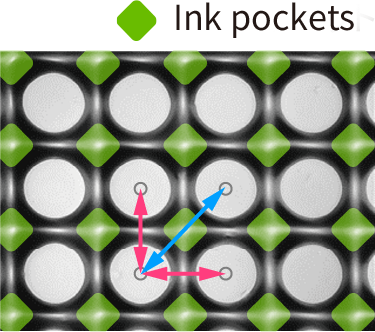

In honeycomb patterning, adjacent halftone dots are evenly spaced. Compared to halftone dots in orthogonal patterning with a pitch of 400 L, those in honeycomb patterning with an equivalent pitch have 1.5 to 1.6 times as many pockets that can hold ink, enabling finer ink application.

| Patterning | Conventional halftone dot patterning Orthogonal patterning |

New halftone dot patterning 1 Honeycomb patterning |

|---|---|---|

| Screen ruling (L) |

400 L | Equivalent to 400 L |

| Image of halftone dots |   |

|

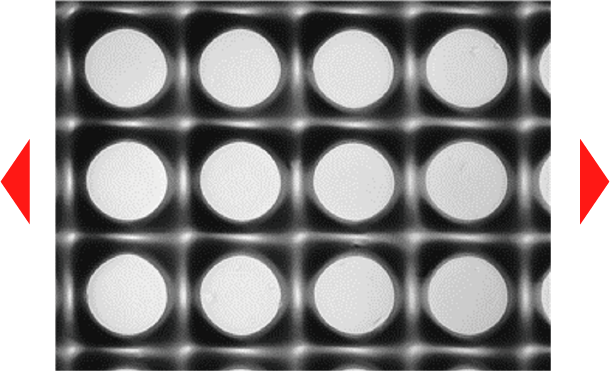

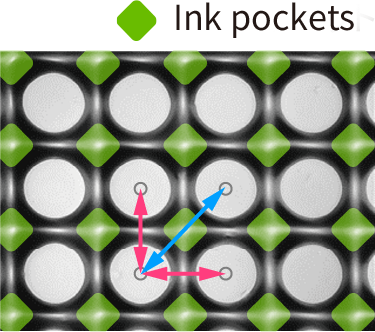

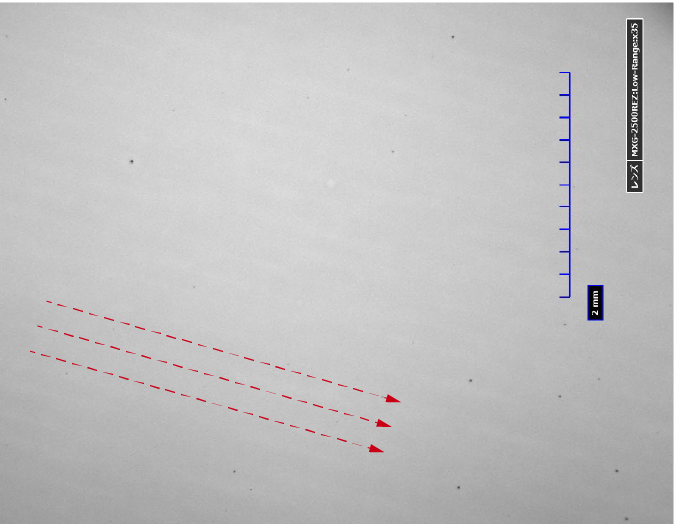

| Halftone dot pitch | The vertical and horizontal pitches (red arrows)are the same. The diagonal pitch (blue arrow) is longer than the vertical and horizontal pitches. |

The pitches in six directions (red arrows)are all the same. |

| CV 【cm³/m²】 |

4.0–5.0 | 4.0–5.0 |

| Print result | With diagonal moiré  |

Without moiré  |

Honeycomb patterning description video (English)

Highly versatile

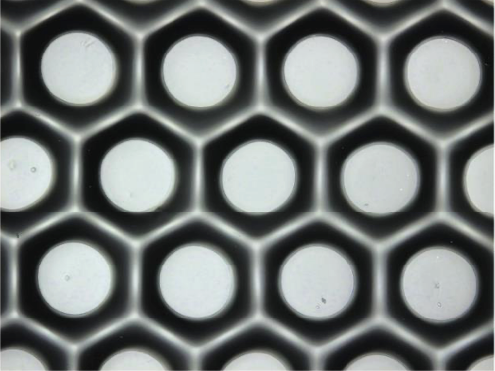

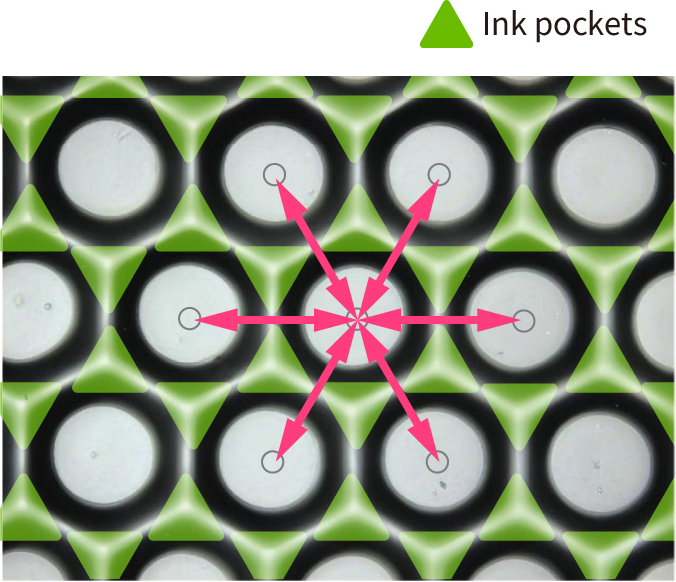

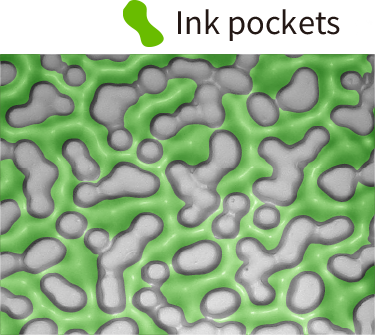

Isotropic patterning

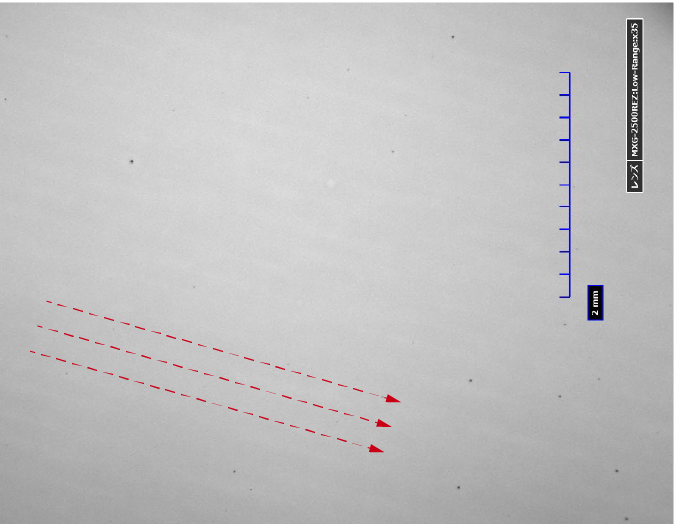

The isotropic patterning, which eliminates pitch regularity, controls moiré, which is a problem that is characteristic of regular patterning.

| Patterning | Conventional halftone dot patterning Orthogonal patterning |

New halftone dot patterning 1 Isotropic patterning |

|---|---|---|

| Screen ruling (L) | 400 L | |

| Image of halftone dots |   |

|

| Halftone dot pitch | The vertical and horizontal pitches(red arrows)are the same. The diagonal pitch(blue arrow)is longer than the vertical and horizontal pitches. |

All halftone dot pitches, vertical and horizontal, are random. |

| CV 【cm³/m²】 |

4.0–5.0 | 3.5–4.5 |

| Print result | With diagonal moiré  |

Without moiré  |