Assembly systems for precise equipment

Introduction

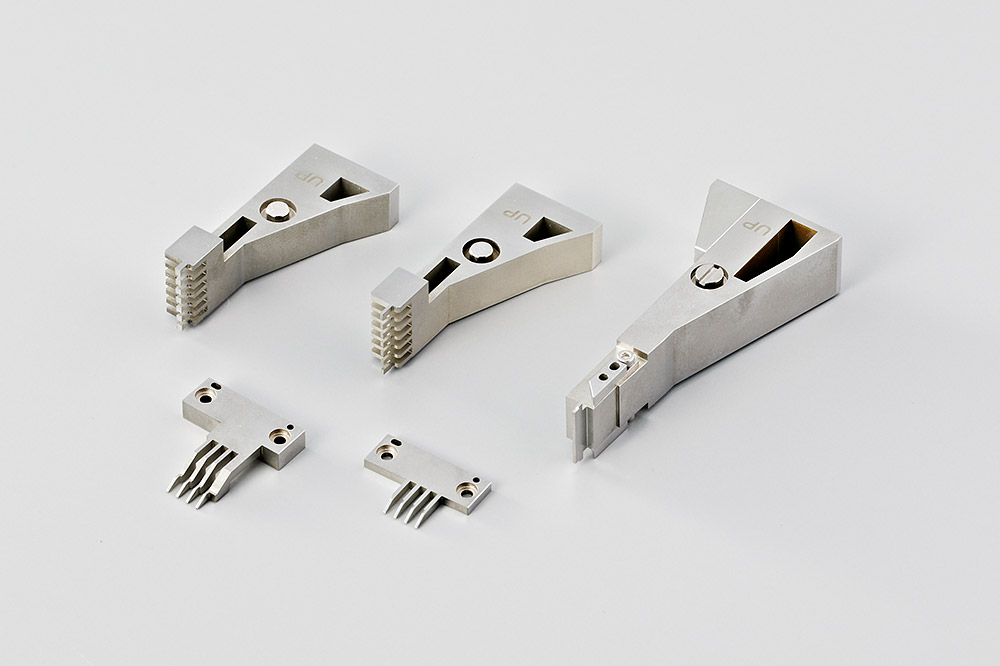

We supply fully automated assembly systems for a wide range of appliances: from tightening screws to building up HDD drives, suitable to use with microparts and precise elements. Our products can be characterized as highly innovative, and can be easily adjusted according to our customers’ needs.

Please feel free to ask us for more details.

- Clean room specification equipment is also available.

- Full support from design and development till production.

- Also available from our Chinese manufacturing base.

Characteristics

Precision

assemblyPrecisely assembles from parts pickup to insertion.

Positioning

feedback

functionCamera or sensor measures the position when mounting the part, calculate the difference from master data and position correction is performed automatically.

Cleanroom

specification

availableWe provide cleanroom compatible equipment for products require assembly in cleanroom environment, such as HDD.

ESD対応

Experienced in assembling HDD that may affect parts with ESD.

Inspection

technologyEquipment specialized for products to be inspected by narrowing down the functions of general measuring instruments.

Tape

applicationFrom tape feed mechanism to tape paste, done without air bubbles. We can also suggest tape materials to our customer.

This product solves these problems.

By automating the work that operators have done manually, the system will handle 24 hours production, stabilize quality, and increase production volumes.

Results and experience

- Assembly equipment and assembly lines for HDD discs

- Fully automated image elements assembly devices

- All types of automated screw fasteners

- Fully automated parts kitting equipment

- Automated laser welding systems

- Other types of custom-made precise assembly equipment and assembly lines

From agreement to delivery: flow

Delivery takes approximately 2 to 9 months after receipt of order, depending on the volume of the device.

![]()

1.Inquiry (perform sample test, etc. as needed.)

![]()

2.Meeting (we will ask you what kind of equipment you need)

![]()

3.Proposal and quotation (proposal of process and equipment specification)

![]()

4.Order

![]()

5.Design, material arrangement, manufacturing, and adjustment

![]()

6.Onsite customer acceptance inspection and training.

![]()

7.Packing and shipping

![]()

8.Installation, adjustment, and flow operation confirmation