Static ultrasonic soldering tank – KDB series

Introduction

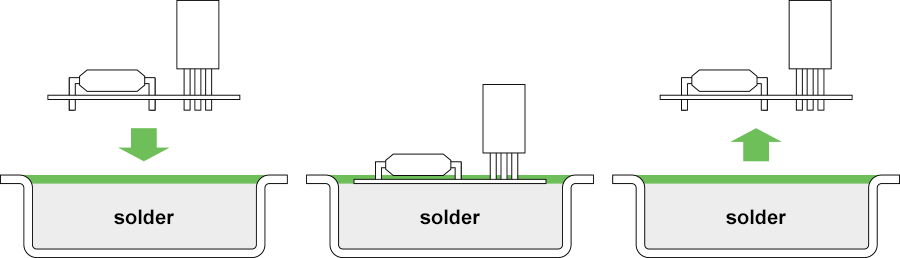

The special solder “Cerasolzar” melted in a static soldering tank and dip soldered.

It is used for coating/soldering of aluminum, ceramic PCBs and outer surfaces of electric discharge tubes (electrodes, structures etc.)

Pros of ultrasonic dip method

- Large amplitude, large output, large cavitation effect distance (gap between material and vibration surface.)

- Preheating with melted solder makes it easy for cavitation to occur.

Cons of ultrasonic dip method

- Difficult to selectively solder.

- Hard to change solder.

Application

All types of coating solder

- Aluminum components

- Ferrite components

- Glass components

- Silicon wafers

- Ceramic components

- Semiconductor chips

- Metals etc.

Multiple material soldering and sealing

- Light fiber terminals

- Ceramic tubes and lead lines (for sensors)

- Glass tubes and lead lines (reed relays)

Pasting together multiple bonded materials

- Sensors

- Optical components

- Spare parts for machines

- JIGs

Specification

| Power source | AC100V 50/60Hz 800VA |

|---|---|

| Temperature | Typically around 400 Celsius |

| Transducer | Bolt tightening Langevin type 18-20 kHz |

| Generator unit | Automatic frequency tracking; output 400W max |

| Supplied nitrogen gas | Depending on application, max 30 l/min |

| Soldering tank size | dia48mm (Could be chosen from between several size depending on the type of job) |

| Dimensions | 370(W)×530(H)×300(D)mm |

From agreement to delivery: flow

Delivery takes approximately 3 months after receipt of order, depending on the volume of the device.

![]()

1.Inquiry

![]()

2.Meeting

![]()

3.Proposal and quotation

![]()

4.Order

![]()

5.Shipment in approximately 3 months