Ultrasonic Dipping with parts scudding ACSS-Scudding-2900

Introduction

This equipment is used to bond electrodes to glass substrates for solar cells, light dimming glass, organic EL, etc.

It is impossible to solder glass using general soldering iron, but our special solders and ultrasonic soldering technology make it possible to solder on glass perfectly.

By bonding copper rectangular wire coated with special solder to the soldered area, it becomes electrode wiring for extracting charge from solar cells and for applying voltage to dimming glass, etc.

Characteristics

Jet

flow

mechanismEnsures supply of pure solder at a stable liquid level by lifting the solder from the bottom of the solder tank.

Nitrogen

purgeIncreases the surface tension of solder and allows dipping of narrow pitch components without solder bridge.

Wide

hornIncreases part feed speed by applying ultrasonic waves in a wider area

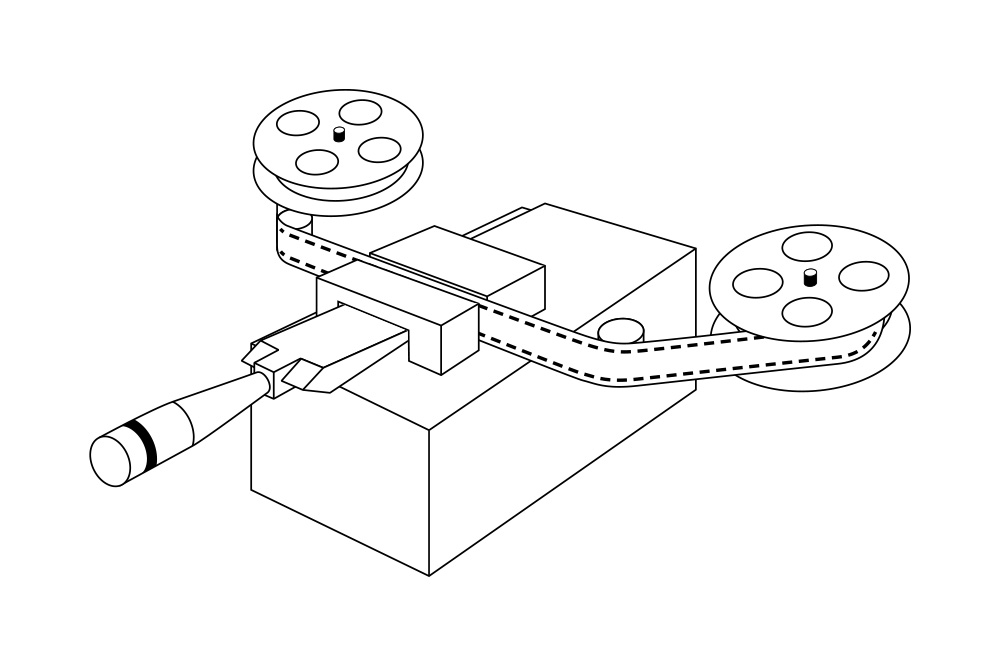

Roll

to

rollContinuous material supply

This product solves these problems

Using flux causes problems such as dirt, deterioration of parts, and rusting of equipment. For narrow pitch components,the effect of flux wetting can also cause solder bridging on the terminals.

With ultrasonic dipping, it is possible to dip components without flux.

Results and experience

| Tin Plating on Aluminum Wire | Continuously tin-plating single aluminum wire in a roll-to-roll method with an ultrasonic vibration unit. |

|---|---|

| Narrow pitch pattern solder coating | Uses ultrasonic waves and nitrogen purge to enable solder coating without bridging to narrow pitch patterns such as QFP, BGA, and antenna wiring. |

Specification

Ultrasonic Dipping with parts scudding

ACSS-Scudding-2900

| Application | Tin-plating of electronic component terminals |

|---|---|

| Overview | Tin plating while continuously feeding parts in progressive feed |

| Workpiece | Various types |

| Ultrasonic wave | 20kHz |

| Soldering material | Various types |

| Characteristics | A mass production model for continuous Tin-plating by using magnets to pick up parts. |